Plate Heat Exchanger Gaskets

PHE Sealing Solutions manufactures PHE gaskets in 9 different materials designed to cater to different applications in various industries. Our compounds are manufactured with the best quality raw materials. We produce gaskets in both, industrial and food grade materials made from the elastomers mentioned below. All food grade gaskets are manufactured as per FDA CFR 177.2600.

WHY CHOOSE OUR GASKETS?

Mould

All gasket molds are manufactured within our dedicated facility using the most sophisticated processes which include Scanner, CAD/CAM centre, CNC machining and Mould Maintenance. Owing to our experience and backed by our professional team, new molds of PHE gaskets are developed and are ready for production within 4-5 weeks.

Production

Our facility includes advanced compression molding presses, in-house mold manufacturing, compounding and testing facilities. We have a range of over 300 molds and we are capable of manufacturing 300,000 gaskets a year with the largest size of 3000×1200 mm. Our in-house laboratory is well equipped with machines for rheometric,

tensile, elongation, hardness, compression and ageing properties.

Compounding

Our formulations are specially developed for manufacturing high quality plate heat exchanger gaskets. We carefully select grades of rubbers and chemicals, which are sourced from authorized distributors of brands such as Arlanxeo, Dupont and Akzo Nobel etc. Food grade gaskets are manufactured as per FDA 21 CFR 177.2600. Our In-house compounding and testing facility allow us to provide customized solutions. We specialize in manufacturing gaskets in HNBR, Viton and Viton G.

Short Lead Times

We maintain an extensive stock of raw materials, finished product and plates to offer very short lead times. Depending on the quantity, we can dispatch material on the same day. We have reliable logistic partners to ensure fast delivery times via Air or Ship across the world. For annual maintenance contracts, we offer customized solutions to reduce maintenance downtime.

Quality

PHE Sealing Solutions is an ISO 9001:2015 certified company for manufacturing Plate Heat Exchanger gaskets. We are one of the few manufacturers that offer 100% press cured gaskets. Advantages include better chemical and temperature resistance and a longer life. Our gaskets contain atleast 50% polymer content and come with a guarantee for any manufacturing defect. Our gaskets are manufactured to provide better lifetime, efficiency and performance, which will help extend maintenance cycle and save cost to the owner.

PHE SEALING SOLUTION’S GASKET TESTING MANUAL

Compound Curing and Processing Test- Rheometric Graph Machine

Physical Inspection by Hand

Rubber Hardness Testing – Shore A

Dimension Measurement – Digital Caliper

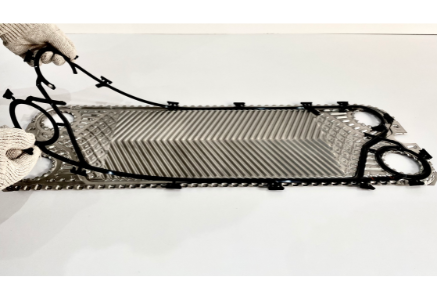

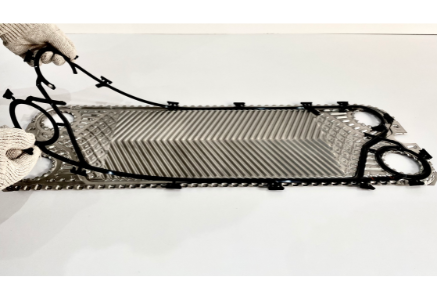

Manual fitment of each gasket on the plate.

ELASTOMERS

| GASKET MATERIAL | TYPICAL RANGE | TYPICAL APPLICATIONS |

| NBR | -15°C to 120°C | Dairy Products, beverages, pharmaceutical and biochemical media, gasoline, industrial and vegetable oils, alkalis and organic solvents |

| NBR HT | -10°C to 130°C | High Temperature vegetable & mineral oil, fatty acids, crude oil |

| EPDM | -35°C to 150°C | Milk, and other low-fat operations, water and steam, inorganic and polar chemicals |

| EPDM HT | -35°C to 160°C | High Temperature Steam media, |

| HNBR | -15°C to 160°C | Mining, high temperature oil, steam, high temperature fatty acids and vegetable oils |

| BUTYL | -10°C to 150°C | Alkali, acids, aldehydes, ketones, phenols and some esters |

| VITON A/B | -15°C to 230°C | Oils, fuels, lubricants and most mineral oils, mineral acids, high temperature vegetable oil |

| VITON G | -15°C to 230°C | Organic solvents, chemicals, concentrated inorganic acid, sulphuric acid, steam and hot water |

| CHLOROPRENE | -20°C to 80°C | Refrigeration applications |