Plate Heat Exchanger Plates

PHE Sealing Solutions maintains a stock of over 30,000 heat exchanger plates for various models of ALFA LAVAL, GEA, APV, SONDEX, TRANTER, THERMOWAVE, SWEP and many more. Our extensive stock allows us to provide immediate delivery, be it for a single plate or an entire plate pack. Moreover, plates for special requirements of corrugation, thickness and material can be arranged on order.

We guarantee the compatibility of each plate sold with a warranty equivalent to OEM.

We stock plates for the following metals/alloys in our inventory

AISI 304

AISI 304

AISI 316L

AISI 316L

TITANIUM

TITANIUM

HASTELLOY C-276

HASTELLOY C-276

NICKEL

NICKEL

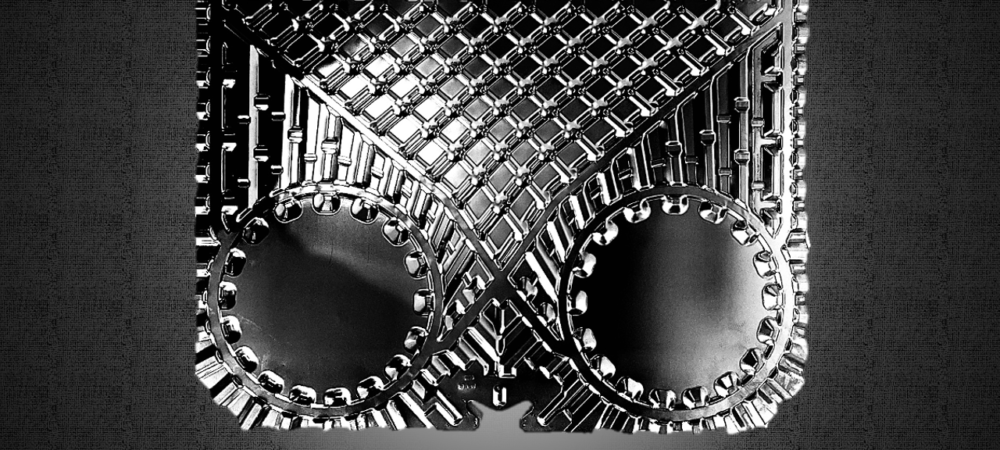

Plate Technology

PHE Plates are designed to transfer thermal energy through the corrugations of the plate as it provides the most optimum heat transfer area. In order to maintain a consistent transfer of heat between two mediums (liquid or gas), the plates have to be compactly stacked against each other. This is ensured by gaskets produced from specialized elastomers with different temperature range, depending on the application. Thus, its highly important to choose the right Plate Heat Exchanger based on one’s heat transfer requirements.

Plate Design

The two main aspects of plate design can be highlighted as the distribution area and the heat transfer area. The corrugated pattern of the distribution area ensures the efficient flow of medium across the heat-transfer area. Whereas, the corrugation of the heat-transfer area produces the essential conditions under which the desirable heat exchange coefficients can be obtained.

High Theta and Low Theta (Chevron Design)

High Theta Channel

-

High Turbulence

-

High-Pressure drop

-

More Heat Transfer

Low Theta Channel

-

Low Turbulence

-

Low-pressure drop

-

Less Heat transfer

Titanium Plates

PHE Sealing solutions also maintains an extensive inventory of refurbished titanium plates. Titanium has high corrosion resistance and is therefore used in marine applications where seawater is widely used as a medium to cool down ship engines among various applications. The plates are DP Tested and guaranteed against pinholes and deformations. All our plates and gaskets go through quality inspection before shipment.

With Our office in Alang, Gujrat, the largest ship breaking yard in the world, we directly source good second Titanium Plates.

Services Offered-

![]() Plate Testing: Dye Penetrant Testing & Ultraviolet Crack Testing

Plate Testing: Dye Penetrant Testing & Ultraviolet Crack Testing

![]() Plate Cleaning: Water and Suitable Chemicals

Plate Cleaning: Water and Suitable Chemicals

![]() Offsite Re-gasketing: Old gasket removal

Offsite Re-gasketing: Old gasket removal

![]() Testing: CIP Testing

Testing: CIP Testing