APPLICATIONS FOR SULPHURIC ACID INDUSTRY

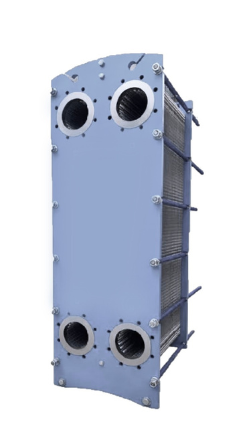

The production of sulfuric acid generates ash and dust, which sets as residue on the corrugated surface of the plate. Due to this, Plate heat exchangers are commonly used in the sulphuric acid production as they are easy to disassemble and clean with lower downtimes. Heat exchanger applications for Sulfuric Acid are mainly to cool the acid with a cold-water media during its various stages of production. The following production processes use heat exchangers either directly or indirectly for thermal heating or cooling.

Cleaning and Cooling SO2 Gas

↓

Moisture Removal from SO2 in the drying tower

↓

SO3 Absorption Tower

↓

Final Cooling of Sulphuric Acid

Heat Integration Network

Along with acid resistant and non-corrosive PHE gaskets and plates, PHE Sealing Solutions offers PTFE seals which are highly resistant to acid. These seals provide longevity to the gaskets. We also specialize in PTFE envelope gaskets which are applied mainly as a flange gasket in high chemical resistance applications.

PHE Sealing Solutions specializes in manufacturing and supplying VITON G/ FKM G gaskets and Hastelloy C-276 for Sulphuric acid, Oleum applications and Special chemical applications. For Oleum applications and special chemical applications, where elastomers are not durable, PHE Sealing solutions provide PTFE enveloped gaskets.

Our Products widely used in the Sulphuric Acid industry –

Viton G Gaskets

PTFE Components

PTFE Envelope Gaskets

Hastelloy C-276

Standard Elastomers Used in Sulphuric Acid Industry

|

GASKET MATERIAL |

TYPICAL RANGE |

|

EPDM |

-35°C to 150°C |

|

EPDM High Temperature |

-35°C to 160°C |

|

Viton A/B |

-15°C to 230°C |

|

Viton G/FKMG |

-15°C to 230°C |